LATEST NEWS

Elettrica - Ferrari breaks battery car silence

Richard Bosselman

October 10, 2025

Technical detail about impending four-door that is unlike anything previously made in Maranello has shared.

WITH Ferrari, so much is about the sound - with an electric car, so much often isn’t.

Ferraristi here will have awoken today news some might never have wanted to learn - that this beloved brand is soon to start selling its first car eschewing internal combustion for battery-fed impetus.

Revealed during Ferrari’s Technology and Innovation Workshop, the project that stands as the most significant shift in the company's history has been under development since 2020.

The finished model’s name is yet to be confirmed ahead of next year’s unveiling, but it being referred to as the Elettrica by Ferrari for now.

High-ups briefing at an investor meeting overnight is that four-door, four-seat model will be unlike any Ferrari before it.

Ferrari says the Elettrica is designed to be a new kind of daily Ferrari, combining all-electric performance with comfort, range and space.

It is not a supercar in the traditional sense and, according to the company’s Chief Product Development Officer, Gianmaria Fulgenzi, it will be even more practical than the Purosangue SUV.

As different as it stands to be, it will at least deliver one historic Ferrari recognition - the brand has assured that while the new model lacks an engine, it does have a voice. One that is designed, not simulated.

Rather than using digital soundtracks piped through speakers, Ferrari engineers created a mechanical acoustic system that amplifies the real vibrations generated by the car’s electric motors and power electronics.

A high-precision accelerometer mounted deep within the inverter casing detects these vibrations, which are transmitted through resonant structures in the body to create an audible tone.

“We didn’t want a replica of our ICE, and we didn’t want to invent or synthesise a new sound,” says Ferrari’s NVH and Sound Quality Manager, Antonio Palermo.

“The puzzle was how to extract a sound from something that is silent.”

That challenge was physical, not digital. In a combustion engine, sound is transmitted naturally through the exhaust and intake systems, but in an electric car, there are no moving air columns or pressure waves.

“Here we have a big chunk of stiff metal, and so the sound cannot escape. There is a lot of sound trapped inside, created by the e-motor and the transmission, but it cannot reach our ears.”

The solution was to treat the inverter and its casing like the body of a musical instrument.

“If sound was airborne, we could use a microphone,” Mr Palermo said.

“But sound here travels in a solid, so we need a vibration sensor. That is why we used an accelerometer. It picks up the sound trapped in the metal and returns a signal we can amplify.”

He has likened the approach to the way an electric guitar functions.

“The internal combustion engine can be thought of as an acoustic guitar,” he said.

“The Elettrica is more like an electric guitar. The accelerometer is our pickup. It is not a magnetic sensor; it is a vibration sensor.”

Ferrari says the sound is authentic, belonging entirely to the components of the powertrain.

The technical package for the model confirms it has a 122kWh battery, an expected output exceeding 700kW, and a range of more than 530km, when measured to the NZ-favoured WLTP scale.

Performance targets include a 0-100 kmh time of 2.5 seconds and a top speed of 310kmh.

Ferrari insists the car was designed to maintain the precision, feedback and emotion of the company’s combustion- and hybrid-powered models while meeting future emissions and efficiency goals.

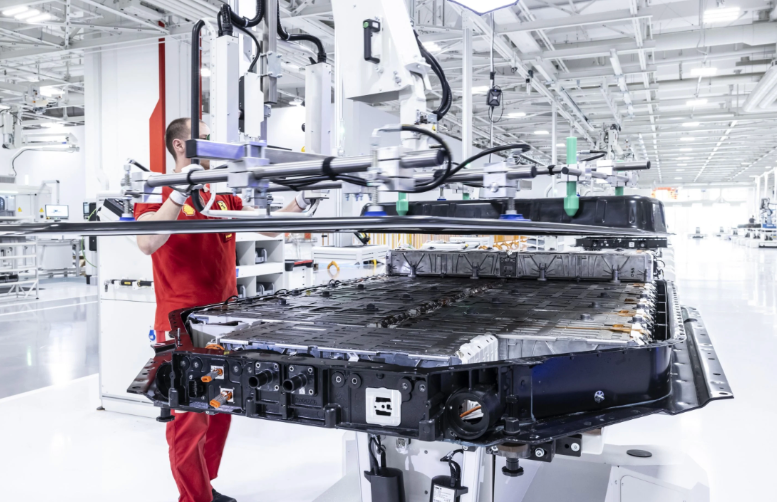

It will be assembled in a new facility in Maranello dedicated to hybrid and electric vehicle production lines.

Power comes from two Ferrari-developed e-axles – one up front and one at the rear – delivering a combined output exceeding 735kW of power in boost mode. The front axle generates a claimed 210kW and 3500Nm of torque at the wheels, while the rear produces 620kW and 8000Nm.

Both feature compact, high-speed permanent-magnet motors with Halbrach-array rotors derived from Formula 1 technology. Ferrari quotes efficiency of up to 93 percent, with motor speeds reaching 30,000rpm at the front and 25,500rpm at the rear.

The Elettrica incorporates an 800 volt electrical architecture and use silicon-carbide power modules for its inverters. These were designed and built entirely in-house. Each axle operates as a self-contained system with dedicated cooling and lubrication.

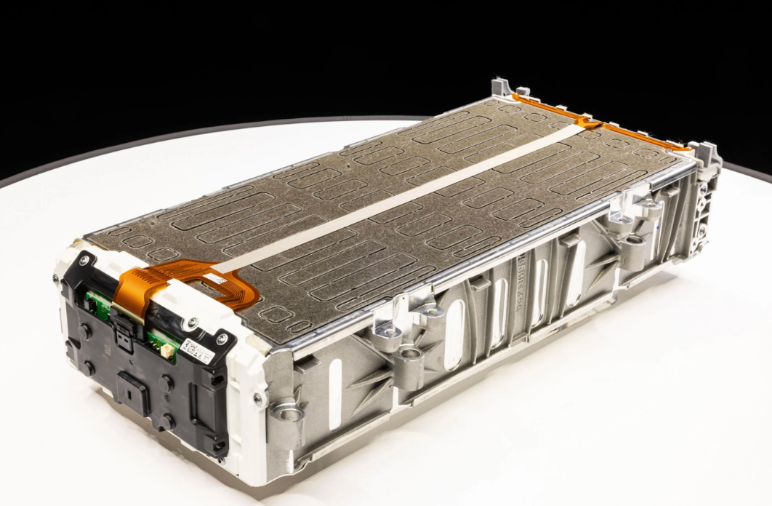

The nickel-manganese-cobalt (NMC) battery is a structural ingredient designed and assembled in Maranello with cells supplied by South Korean battery manufacturer SK On.

The battery supports 350kW DC fast charging and contains 210 cells arranged in 15 replaceable modules, allowing individual components to be serviced or replaced under Ferrari’s Forever programme, which guarantees long-term maintenance and support for electrified models.

SK On has supplied cells for Ferrari’s plug-in hybrid models.

The structural design bolts the pack to the chassis at 20 points, increasing rigidity and lowering the centre of gravity by around 80mm compared with a comparable V8 model.

Cooling channels are integrated directly into the aluminium shell for temperature uniformity and impact resistance. The battery’s mass is concentrated beneath the cabin floor, helping achieve a 47-53 front-rear weight balance and a total weight of 2300kg.